关于TS-J50ZS 四面自动钉角机的操作步骤

Manual of TS-J50ZS automatic framing joint robot from TAISHENG FRAMING EQUIPMENT. this one can handle heavy production very simiple.

Online Order link as below:

Click me to order and see price.

Product Description

|

Name:

|

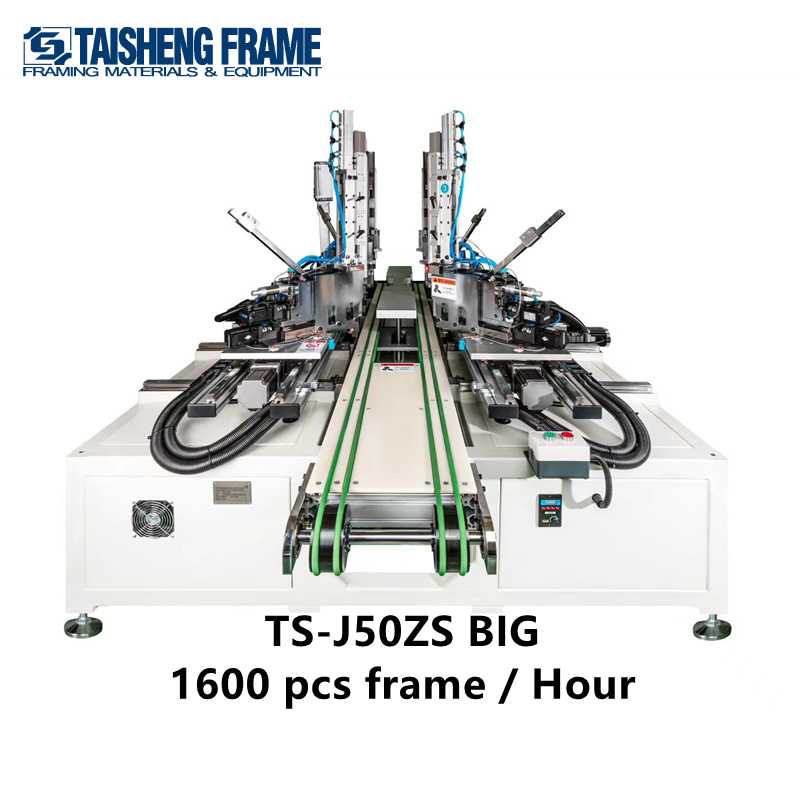

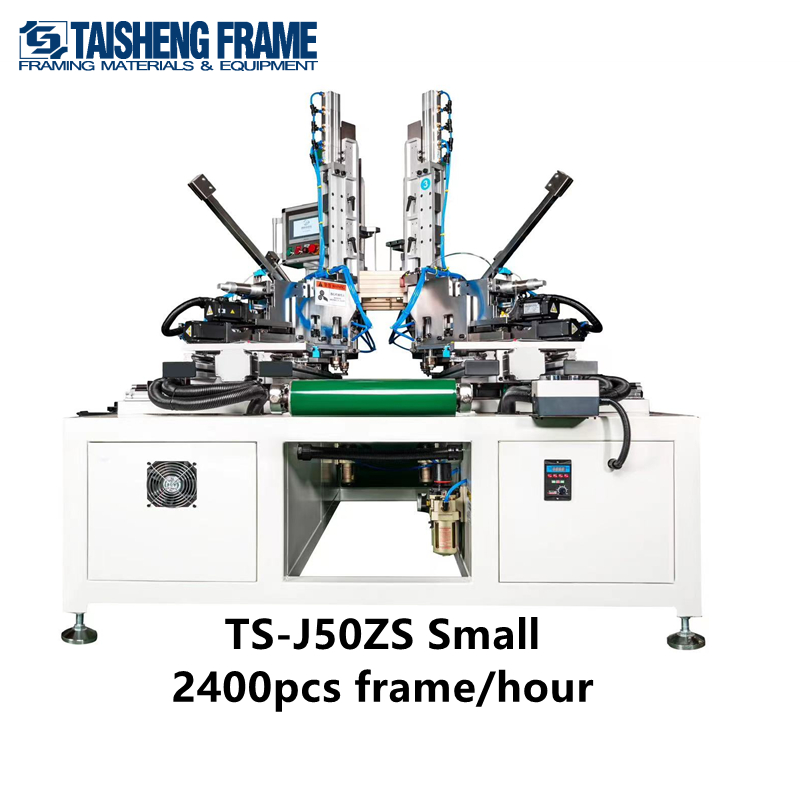

TS-J50ZS Automatic picture frame joint robot for large photo production line .

Canvas Stretcher Bar Underpinner

|

|

Power

|

220V, 50/60hz, 1 phase. If you need change power ,please call us !

|

|

Production capacity

|

Big size 1600pcs-1800/H, Small size 2400pcs/H. Now still Is improving .

|

|

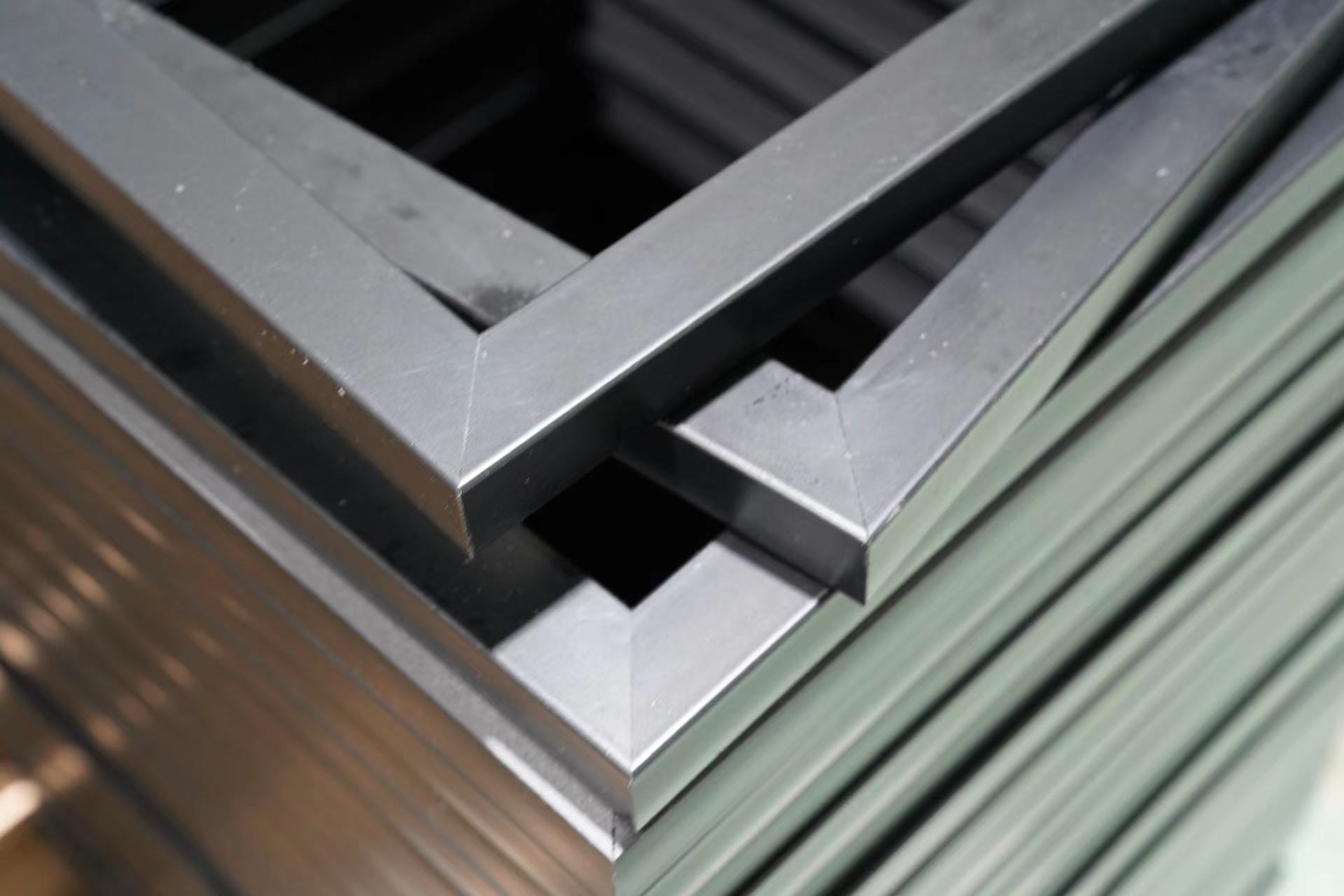

Advantage 1- Machine frame Shape:

|

Made by steel, hard enough , and heavy weight makes it less shake . More durable !

|

TS-J50ZS Big type

Machine size: 220x172x170cm

Packing size: L255CM * W 205CM * H 213CM GW:1770KG

TS-J50ZS Small type

Moulding size: Width-1~4cm Heigth≤3cm

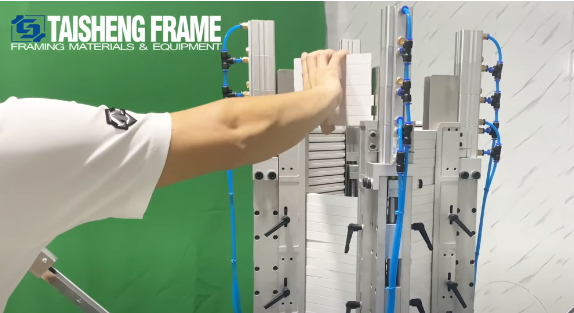

Worker even no need raise hand .It will makes you easy put frame and fast in it from top.

Attention : This will influences many things when it in production .

Worker will be very Comfortable working condition .

Comfortable working will helps company win more ! And win more !

Problem will happen on big size frames .

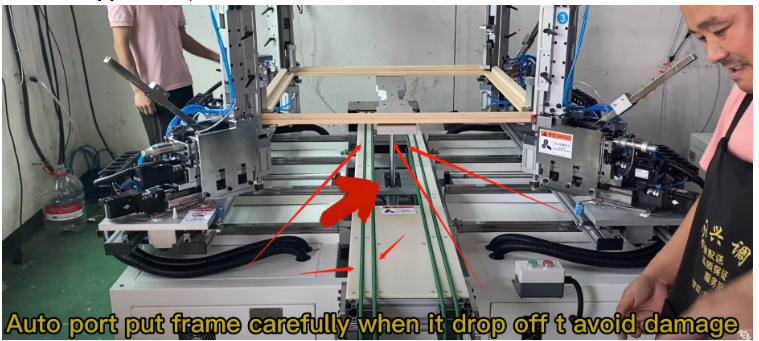

For big frames , we designed a port to park the frames carfully . See the Big size type.

In this way ,frame won't damage . Make it less weight .And all in same position and direction move to next station .

This will be very important for a fast production line.

4 small + strong green conveyor belt ,will make less friction to deliver frames out faster ! This is more durable and worker more safe too.

Frame easy damage or broken belt when it drop off . Position will many different ,worker will collect them not fast .

Advantage 4:

Advantage 5:

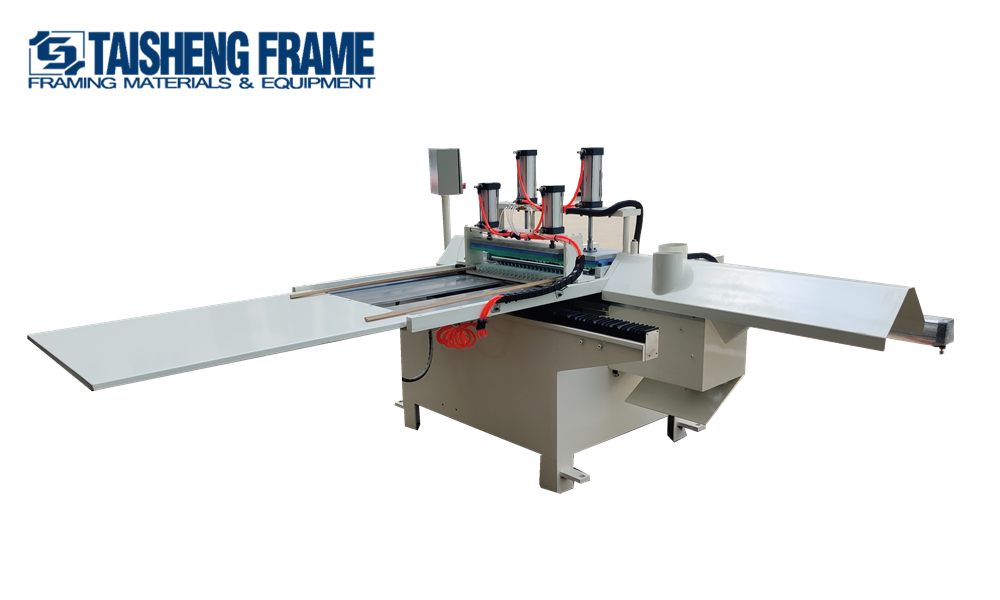

Automatic cutting machine partner :TS-J39 Automatic cutting -28pcs frame cutting in one time!

Click picture Learn more : http://taishengframe.com/en-US/product829.html

WORKING VIDEO:

Automatic Frame Joining PRODUCTION LABOR SAVINGS | FRAME BUILDING INTEGRATION Designed and manufactured for high-volume auto joining of canvas stretcher bars. Average cycle time for four-corner joining is 2 to 6 seconds per frame. Production range up to 1600-2400 joined frames per hour.

TS-J50ZS TAISHENG Frame Robot System suited for high volume automatic frame joining of moulding and canvas stretcher bars. The system consist of a Vertical Feeder that automatically positions the moulding into the four individually controlled joining stations each inserting V-Nails simultaneoulsy in one or multiple positions per corner.

автоматическая фоторамка СКРЕПЛЯЮЩИЙ СТАНОК Скрепляющий станок “TS-J50ZS” больше подходит для багетных мастерских, выполняющих индивидуальные заказы. Удобный, надеждный и производительный станок, прост в управлении. Верхний прижим всегда находится в точке, где вставляется скобка.

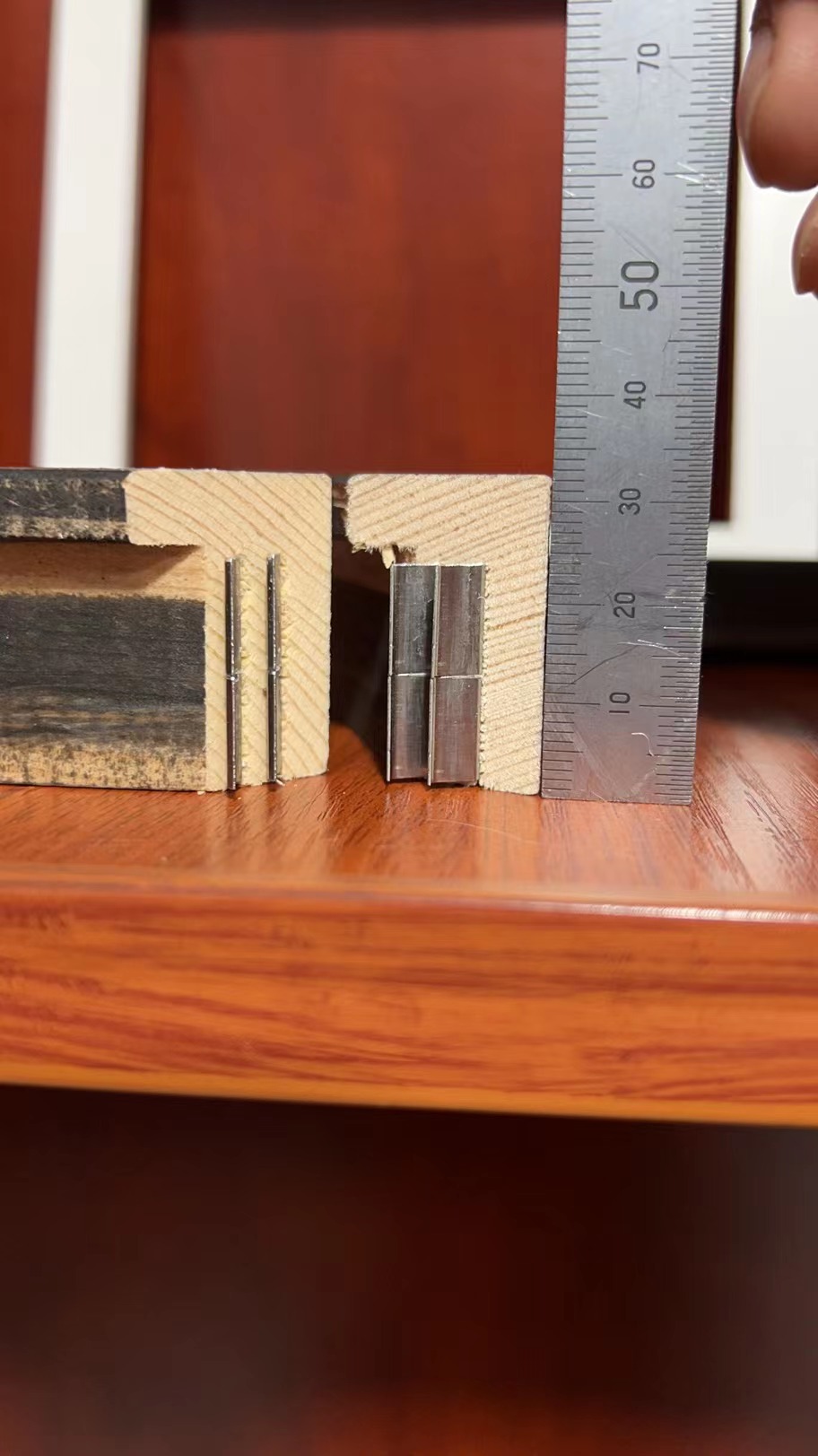

TS-J50ZS automatically underpins four stretcher bars (45° cut) with v-nails.

Frames can be underpinned adjustably with one, two or three v-nails. You can expect production yields of about 30-40 units per minute, depending on if your operator can keep up with the magazine loading and frame output handling.

Format changes are continuously variable and take approximately 2 minutes with no extra tools needed. Through its integration into automated canvas stretching manufacturing,

Online order and more details please check link as below :https://www.alibaba.com/product-detail/TS-J50ZS-Automatic-picture-frame-joint_1600632546687.html?spm=a2747.manage.0.0.68ee71d2R0jPJD TS-J50ZS -Small Automatic Frame Joining robot PRODUCTION LABOR SAVINGS | FRAME BUILDING INTEGRATION Designed and manufactured for high-volume auto joining of canvas stretcher bars. Average cycle time for four-corner joining is 2 to 6 seconds per frame. Production range up to 1800-2400 joined frames per hour.

TS-J50ZS TAISHENG Frame Robot System suited for high volume automatic frame joining of moulding and canvas stretcher bars. The system consist of a Vertical Feeder that automatically positions the moulding into the four individually controlled joining stations each inserting V-Nails simultaneoulsy in one or multiple positions per corner.

Frame Assembly Machine Stretcher Bar underpinner machine vnails joint machine#StretcherBar #canvaspainting